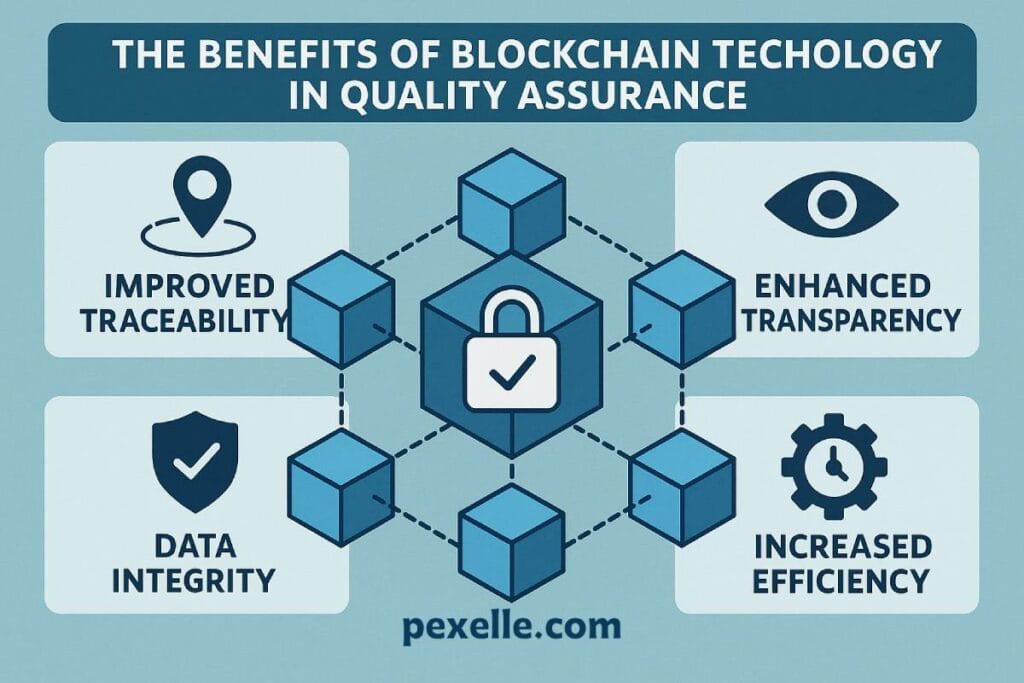

The Benefits of Blockchain Technology in Quality Assurance

In today’s complex and globally distributed supply chains, ensuring consistent quality across every stage of production and distribution has become increasingly difficult. Traditional quality assurance (QA) methods often lack transparency, traceability, and tamper-resistance. This is where blockchain technology—known for its decentralized, immutable, and verifiable nature—emerges as a transformative solution. Integrating blockchain into QA processes can enhance accountability, reduce errors, and foster trust between manufacturers, regulators, and end consumers.

One of the primary advantages of using blockchain in QA is data integrity. Every quality check, certification, or audit record can be timestamped and stored immutably on a blockchain ledger. This ensures that once a record is entered, it cannot be altered without detection. Whether it’s tracking raw materials, environmental conditions during shipping, or the outcomes of product testing, stakeholders can confidently rely on the accuracy of blockchain-logged data. This level of trust is crucial in industries such as pharmaceuticals, aerospace, and food safety where quality lapses can have serious consequences.

Another significant benefit is real-time traceability. Blockchain allows every step of a product’s journey to be transparently recorded—from raw material sourcing to final delivery. If a defect is detected, companies can rapidly trace back to the specific batch, supplier, or production unit responsible, enabling faster recalls and reducing the scope of quality issues. Furthermore, by providing consumers and regulators with a secure digital trail of certifications and compliance checks, blockchain enhances brand reputation and facilitates easier regulatory audits.

Smart contracts also bring automation to QA processes. These self-executing digital agreements can automatically verify conditions, trigger alerts for anomalies, or block products from proceeding if certain criteria aren’t met. For example, if a batch of products fails temperature monitoring, a smart contract could prevent it from being shipped. This reduces human error, improves efficiency, and enforces quality rules with precision.

Finally, blockchain fosters collaborative quality management across supply chain partners. With a shared ledger, suppliers, manufacturers, quality auditors, and distributors can all input and access relevant data securely, without relying on centralized intermediaries. This leads to faster dispute resolution, lower administrative overhead, and increased stakeholder trust.

In conclusion, blockchain technology has the potential to revolutionize quality assurance by introducing transparency, traceability, and trust into every phase of production and delivery. As industries continue to prioritize accountability and efficiency, integrating blockchain into QA frameworks will not only reduce risks but also deliver lasting competitive advantages.

Source : Medium.com

Great resource for finding AI tools! It’s refreshing to see a platform that curates and simplifies the search for innovative solutions. Definitely check out their AI Service section-it’s a game-changer for streamlining workflows.